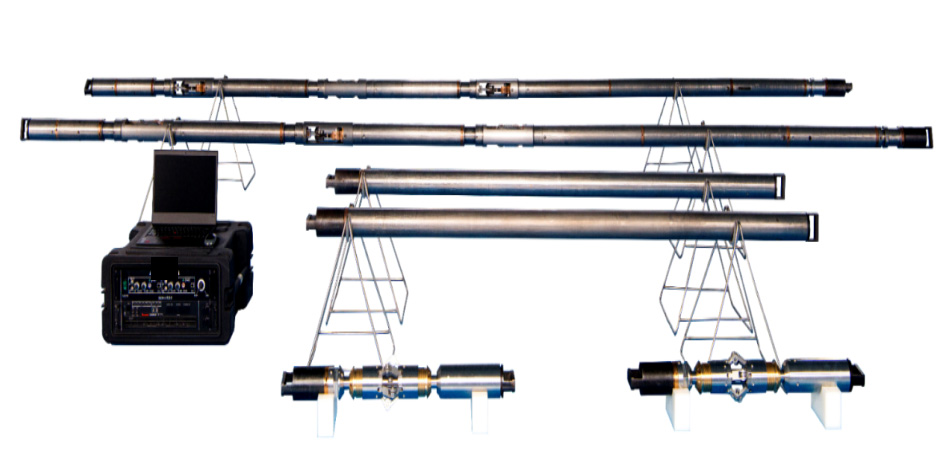

Applicable conditions

Crawler is a downhole equipment delivery tool for cased horizontal wells and highly deviated wells. During the operation of horizontal wells and highly deviated wells, when the downhole equipment cannot be lowered to the target well section by gravity, the crawler can use its own power device to accurately deliver the downhole equipment to the designated position. Compared with the traditional transportation methods such as drill pipe and coiled tubing, the use of crawler to transport downhole tools has the advantages of low labor intensity, low construction risk, time-saving and efficient, long transportation distance and so on.

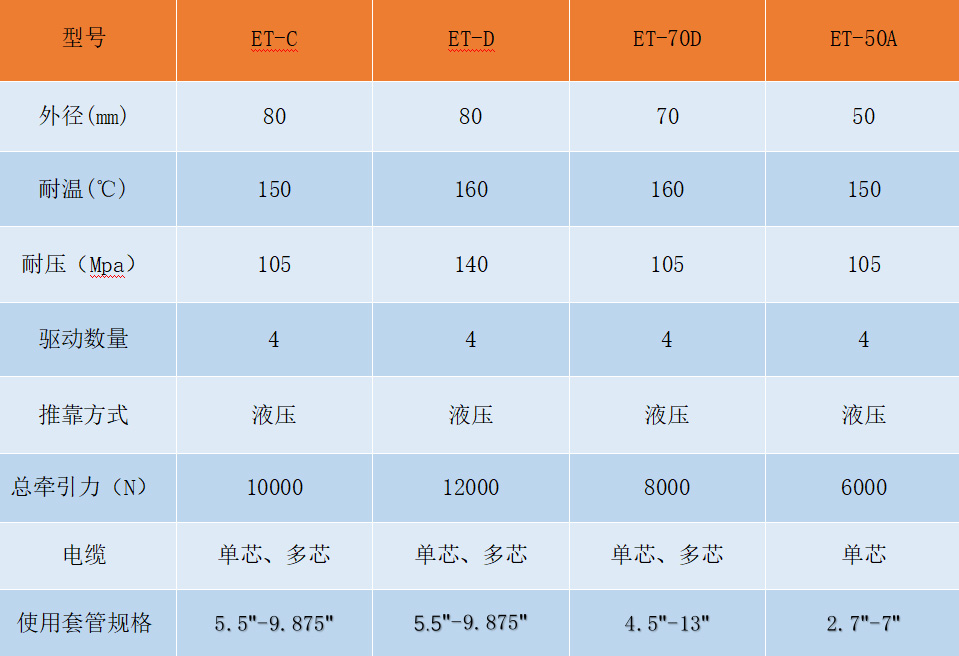

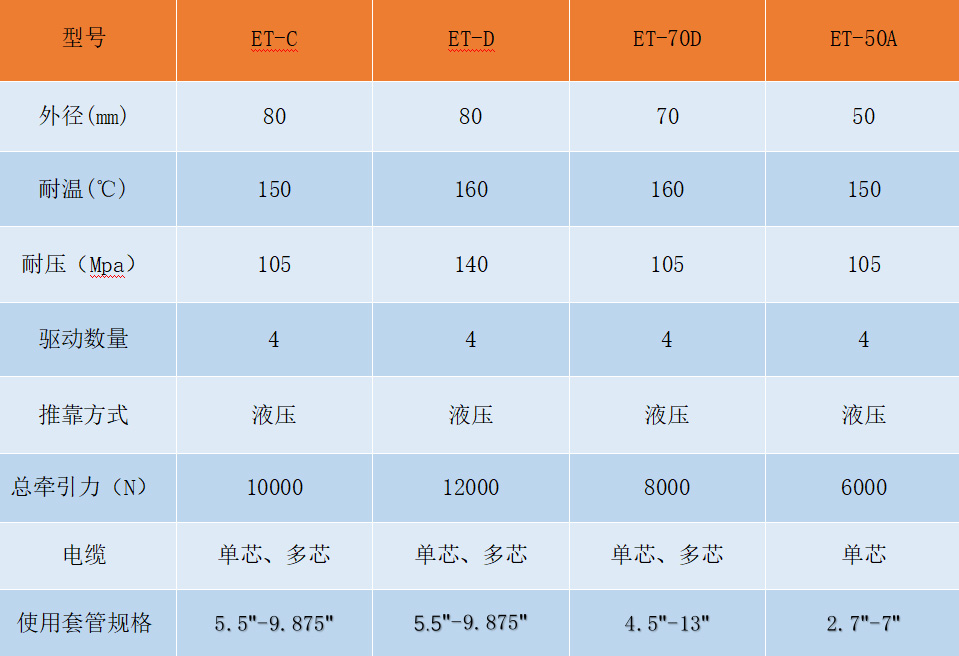

Technical indicators

Technical advantages

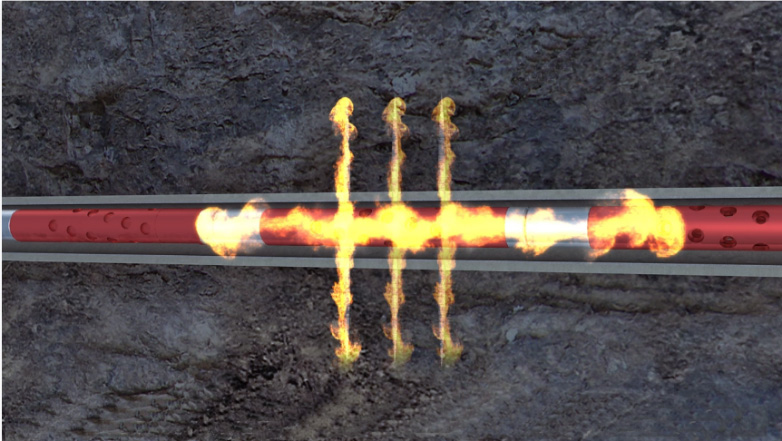

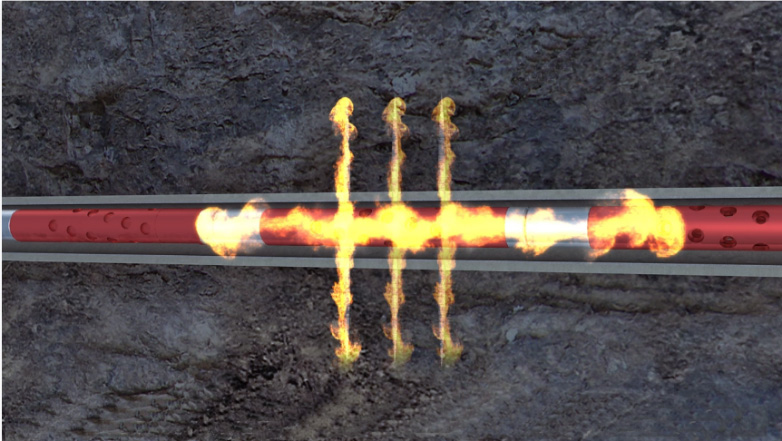

Creeper perforation

The large-scale application of creeper perforation has been realized, and 369 wells have been operated on site.

Airtight conveying

There are many sets of 35MPa, 70MPa, 105Mpa, 140MPa high-pressure and ultra-high voltage cable sealing devices, which can meet the construction of wells with different pressure levels.

Heavy load conveying

The number of driving sections can be selected according to the working conditions. The maximum traction force is 12000n, and the traction speed can reach 8m / min.

Multi core cable transmission

It is suitable for a variety of logging instruments, such as post casing neutron, seven parameters, optical fiber, etc., to carry out horizontal well logging operations.

Complex horizontal well transportation

The movement state of downhole equipment is controlled through the anchor nipple and the reverse movement constraint scheme of crawler, so as to ensure the static or uniform state required by operation and construction, and eliminate the influence of wellbore trajectory on equipment movement.

Upward horizontal well transportation

136 wells have been completed with the maximum deviation of 95 ° and above.

Long distance horizontal well transportation

With long horizontal transmission capacity, 13 wells have been completed in the horizontal section of more than 3000m, and 398 wells have been completed in the horizontal section of 2000-3000m.

Field application

By the end of 2021, the company has completed a total of 1640 well times of crawler construction, including 13 well times of horizontal section length greater than 3000m; 398 wells were completed in the horizontal section of 2000-3000m; 136 wells with a maximum deviation of 95 ° and above; The first section of the crawler was perforated for 369 wells. The one-time completion rate of construction is 99%.